WFE API Globe Valves 3D Demonstration

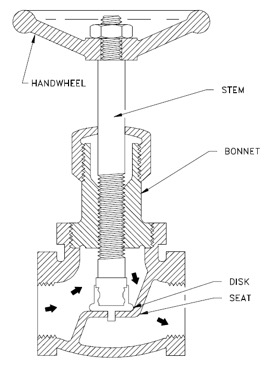

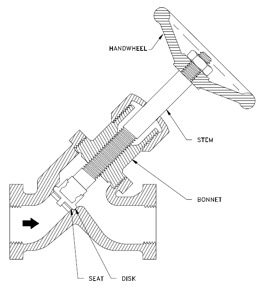

Globe valve is a linear motion valve used to on-off service and throttling service (regulate fluid flow). The structural elements of a typical globe valve are shown on Figure 1 and be the same as those of gate valves.

Wide range of materials are available for globe valve bodies, most commonly are made cast iron, cast steel, forged steel, and corrosion-resistant alloys while mostly using screwed, flanged, and welded body-end connections.

Figure 1. Design of the globe valve

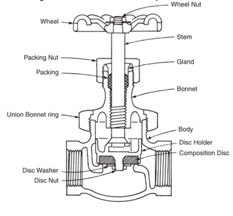

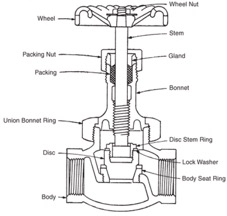

The globe valve can come with different bonnets (union, screwed in and screwed on, flanged, pressure sealed etc.) and stems (inside screw, outside screw, sliding stem), but most of design differences come from the disc (plug) design. Besides conventional disc other common disc designs are tapered plug disc and composite disc. Globe valve seats are either integral with or screwed into the valve body. Many globe valves have backseats, so when the valve is fully open, the disk seats against the backseat which prevents system pressure from building against the valve packing.

Figure 2. Left: globe valve with composition disc. Right: globe valve with plug disc

Globe valves can come with the disk that closes against or in the same direction of fluid flow. When the disk closes in the same direction of flow, the kinetic energy of the fluid aids closing but impedes opening and vice versa. This characteristic is preferable to other designs when quick-acting stop valves are necessary.

Concerning the globe valves valve body design, there are primary three body designs for globe valves: Z-type, Y-type and angle type. Shown on the Figure 1. is the simplest and most common for water applications is the Z-body design, also known as a straight-through globe valve.

Y-body design valves, also known as cross-flow globe valves design reduces the high pressure drop inherent in globe valves. The seat and stem are angled at approximately 45° with the media flow, for a straighter flow path at full opening. The Y-design also keeps the stem, bonnet, and packing in a relatively pressure-resistant envelop.

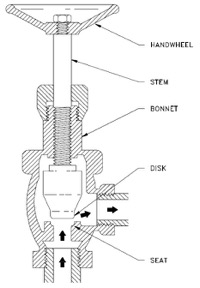

Angle globe valves, illustrated on Figure 3. are designed so that the inlet and outlet are perpendicular. They are used for transferring flow from vertical to horizontal. Fluid is able to flow through with only a single 90° turn and discharge downward more symmetrically than the discharge from the Z-type.

Figure 3. Left: angle globe valve. Right: Y-type globe valve

The operation - flow through a globe valve follows a changing course: the fluid enters the valve parallel to the valve port and after two 90° turns leaves the valve again parallel to the valve port.

As shown in Figure 1, the globe valve seating is parallel to the line of flow, disk (plug) can be totally removed from the flow path when valve is fully open, or it can completely close the flow path when valve is in closed position.

Globe valve regulates fluid flow by varying the size of the port opening through which the fluid flows. This is achieved by varying the position of the disc - perpendicular movement of the disk (plug) from and toward the valve seat. All contact between the seat and the disc ends when flow begins. This characteristic gives the globe valve good throttling ability, which permits its use in regulating flow.

Globe valves can be used in a wide variety of industrial applications.

A composition disc is not recommended for throttling service thus is highly regarded for dependable, tight seating for hard-to-hold fluids, such as gas and compressed air. They can usually tolerate the embedment of dirt without leaking.

Because of its configuration, the tapered plug disk provides better throttling than other globe valve designs. The flow-control element has a wide seating contact with the tapered seat. The configuration results in a directly proportionate relation of size of seat opening to the number of turns of the hand wheel and permits close flow regulation. All contact between the seat and the disc ends when flow begins. This is a distinct advantage for the throttling of flow with a minimum of wire drawing and seat erosion.

The conventional disc design is recommended for positive shut-off of liquids but is not recommended for throttling service.

Angle body design has particular advantage that it can function as both a valve and a piping elbow. For moderate conditions of pressure, temperature, and flow, the angle valve closely resembles the ordinary globe. The angle valve's discharge conditions are favorable with respect to fluid dynamics and erosion.

The Y-design provides stem, bonnet, and packing in pressure-resistant envelop which makes Y-design suitable for high pressures and other severe services Globe valves used for steam applications are mostly welded into the system, the top-entry maintenance makes globe valves ideal for the power industry. Also, the disc and seat can be quickly and easily reseated or replaced, which makes the use of globe valves ideal for applications where frequent maintenance is required.

Figure 4. Globe Valves in use

This article is just a brief introduction to globe valves, if you have any question or need further information about globe valves or other valves, please contact us via mail sales@wfecn.com or direct call +86 (577) 5775 5599.

Copyright 2021 © Winning Fluid Equipment. All Rights Reserved. Powered by: Otree Privacy Policy