The challenge in making a material choice is actually verifying that the chosen material best fits the application. This involves taking into account working conditions and flow media properties.

Most important concerning the working conditions is to know the pressure and temperature ratings and for working media is to take in consideration corrosive and erosive properties. Additionally, it might be needed to consider thermal and physical shock, line stress and fire hazards.

In general engineer assigned for material selection should be familiar with ASME B16.34 code requirements. This standard, amongst other subjects, cover requirements for pressure-temperature ratings, dimensions, materials and other aspects of valve design, manufacturing and testing. ASME code is generally accepted worldwide (e.g. US, Canada, Australia) but there are other standards that cover this subject and rule design and material selection. For example, in Europe standard series EN 12516 cover material selection for the valves.

Be sure to get knowledgeable with this codes before getting into material selection for the valves, because if not mandatory (in some cases are mandatory) materials proposed for valves in this standards come from the real life experience and therefore are tested and proven to be suitable for specific service in practice.

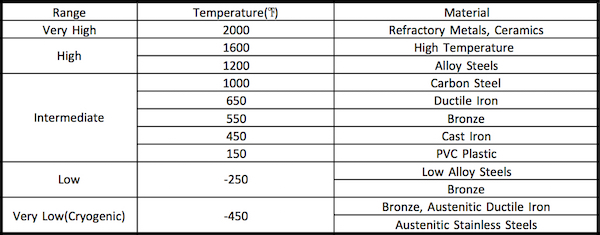

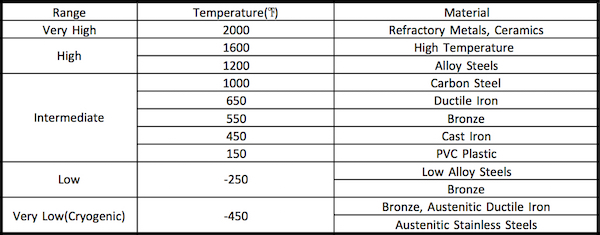

Broadly speaking when considering temperature limitations of different groups of materials Table 1. should be used as general reference for material selection.

Table 1.

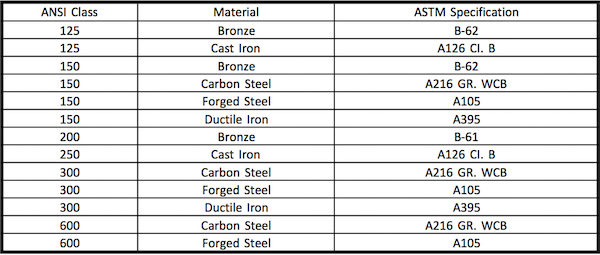

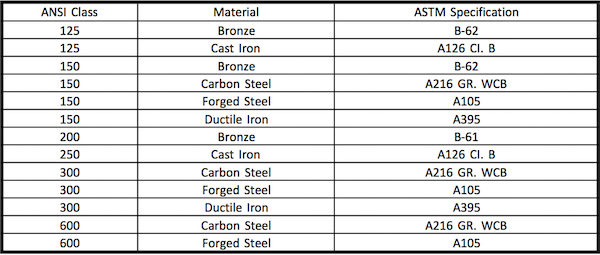

In some cases a compromise must be reached in selecting a material. Some service conditions require use of exotic alloys and metals to withstand particular corrosive properties of the flowing fluid. These materials are much more expensive than common metals, so economy may also be a factor in material selection. Table 2 shows ASTM materials widely used for valve bodies and bonnets.

Table 2

But, the majority of valve applications handle relatively non-corrosive fluids at not so high pressures and temperatures to require any exotic material. For this reason, cast carbon steel is the most commonly used valve body material and can provide satisfactory service at much lower cost than the exotic alloy materials.

Some commonly used carbon steel materials for valve body are WC steel (Wrought Carbon), ASTM A216/A216M and A105 as the forged version of this steel with grades WCA, WCB and WCC.

Of the three steel grades WCB is the common grade for regular temperature applications for cast steel valves. ASTM-A216 WCB is acceptable where corrosion resistance is not important for the temperature range of -20*F to 800?F.

WCC is also widely used steel material for valve bodies in moderate services such as air, saturated or superheated steam, non-corrosive liquids and gases. WCC is not used above 800?F as the carbon rich phase might be converted to graphite. It can be welded without heat treatment unless nominal thickness exceeds 1-1/4 inches.

There are variety of different materials used apart from carbon steels for valve body, lets mentions some most widely used that are in accordance to the ASME B16.34:

- Cast Iron (ASTM A126) in inexpensive, non-ductile material used for valve bodies controlling steam, water, gas and non-corrosive fluids. It is used for relatively low temperature and pressure ratings.

- Cast Chromium-Molybdenum Steel (ASTM A217 Grade C5)!In the past it was commonly specified for applications requiring chromium-molybdenum steels. However, this material is somewhat difficult to cast and has a tendency to crack when welded. WC9 has successfully replaced C5 in many applications, but C5 continues to be used in refinery applications where its higher chromium content provides better resistance to high-temperature sulfidic corrosion.

- Cast Chromium-Molybdenum Steel (ASTM A217 Grade WC9) has a superior casting and welding properties. WC9 has successfully replaced C5 in most applications, especially in steam and boiler feed water service. The chromium and molybdenum provide erosion-corrosion and creep resistance, making it useful to 1100?F. WC9 requires preheating before welding and heat treatment after welding.

- Cast Type 304L Stainless Steel (ASTM A351 Grade CF3) is a good material offering for chemical service valves. 304L is the best material for nitric acid and certain other chemical service applications. Optimum corrosion resistance is retained even in the as-welded condition.

- Cast Type 316 Stainless Steel (ASTM A351 Grade CF8M) goes as industry standard stainless steel body material. The addition of molybdenum gives Type 316 greater resistance to corrosion, pitting, creep and oxidizing fluids compared to 304. It has the widest temperature range of any standard material: -425 ᵒF to 1500 ᵒF. The rough castings are heat treated to provide maximum corrosion resistance.

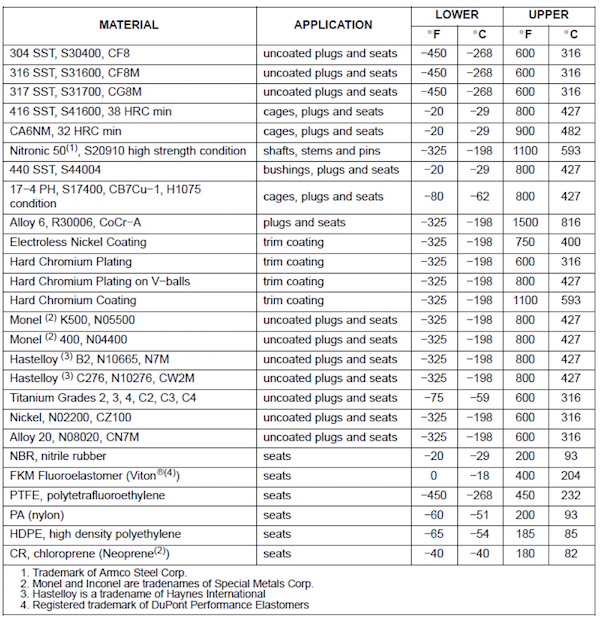

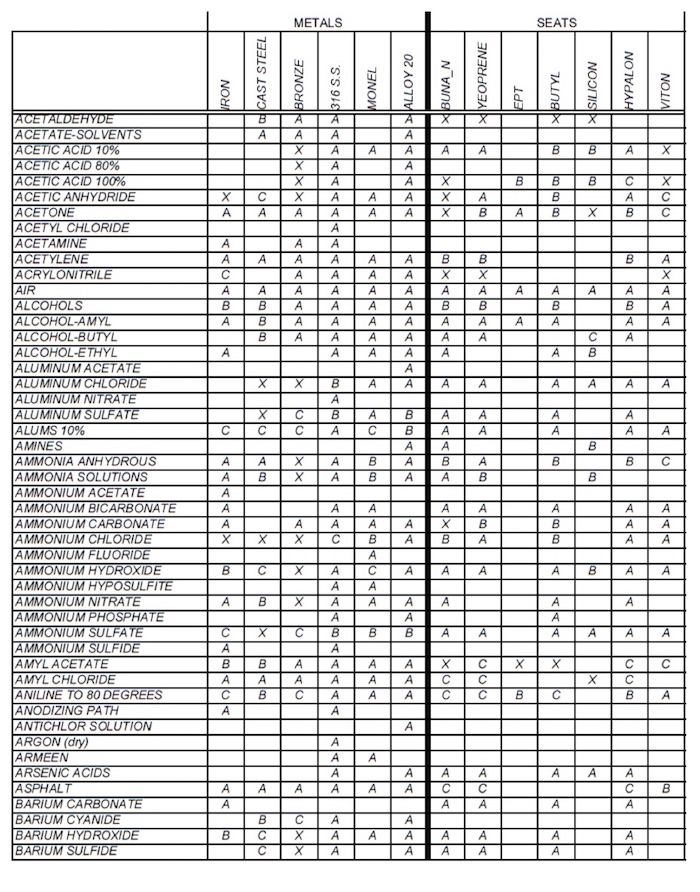

The trim typically includes a disk, seat, stem, and sleeves needed to guide the stem. Valve trim materials in relation to temperature limits should be selected in according to Table 3.

Table 3. Trim material temperature limits

Besides some more or less common materials, alloys have been developed for elevated temperatures and extreme environments. For example Stellite (mostly Stellite 6) - is an alloy used for demanding mechanical and chemical service over a wide temperature range up to 147 ᵒF and is also known for its anti-galling properties and a strong resistance to impact/cavity corrosion. Monel is a series of nickel alloys typically used in high corrosion environments like in seawater valves.

Power to operate a valve is applied through a stem or shaft which passes through the valve body. For large valves the load to operate the valve can be high so that high strength materials are preferred. However, these must have adequate corrosion resistance for the fluid being handled.

For coated carbon steel or cast iron bodies the usual choice for stems is a stainless steel. For deaerated seawater or brine grad 316 stainless steel is suitable but for aerated seawater and brine this can suffer pitting and crevice corrosion - particularly at seals.

Stems are sometimes made in brass alloys but these will suffer dezincification unless receiving cathodic protection - for example from an uncoated cast iron or carbon steel body.

The rough surface which this corrosion produces can then damage the seal when the valve is operated causing leakage. Grade 316 stainless steel can be used if the valve body is Ni Resist cast iron as this provides cathodic protection. Product water systems often use grades 410 and 430 stainless steels. They have a strength advantage over the austenitic grades such as grade 316 but have lower resistance to chloride pitting. Care is needed when using these grades with reverse osmosis product waters, which have appreciable chloride contents, and if seawater is used for hydro testing.

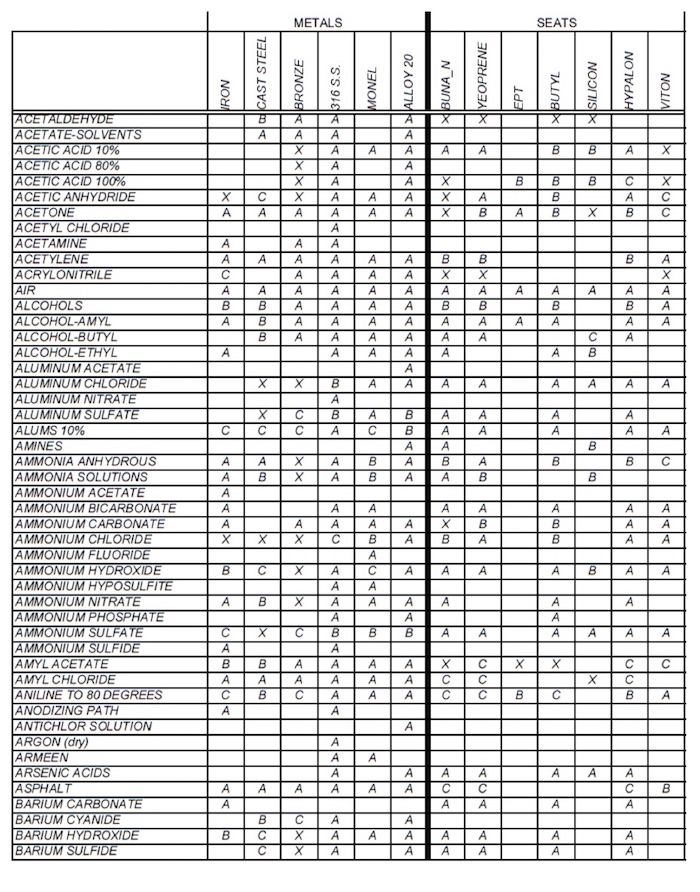

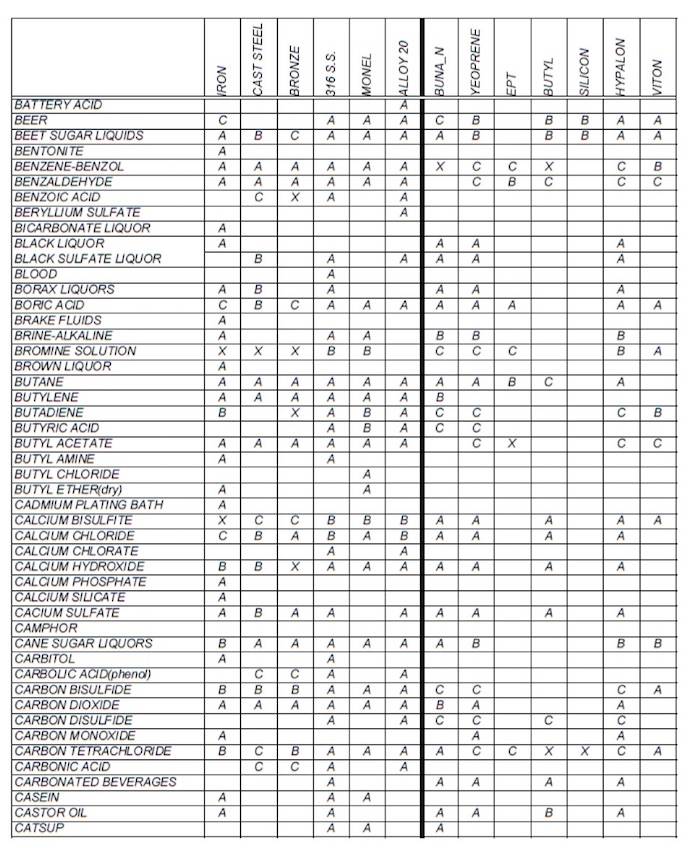

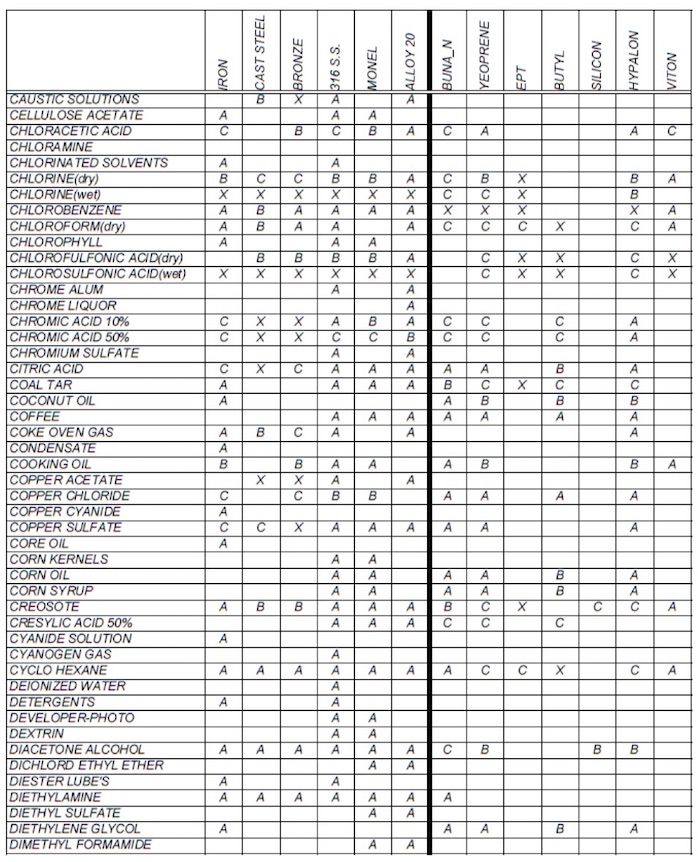

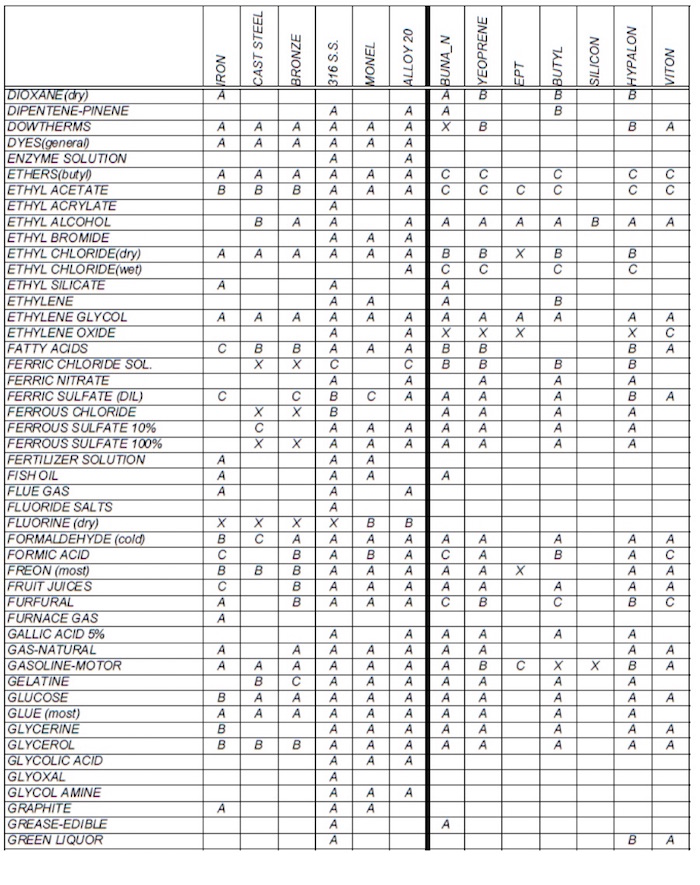

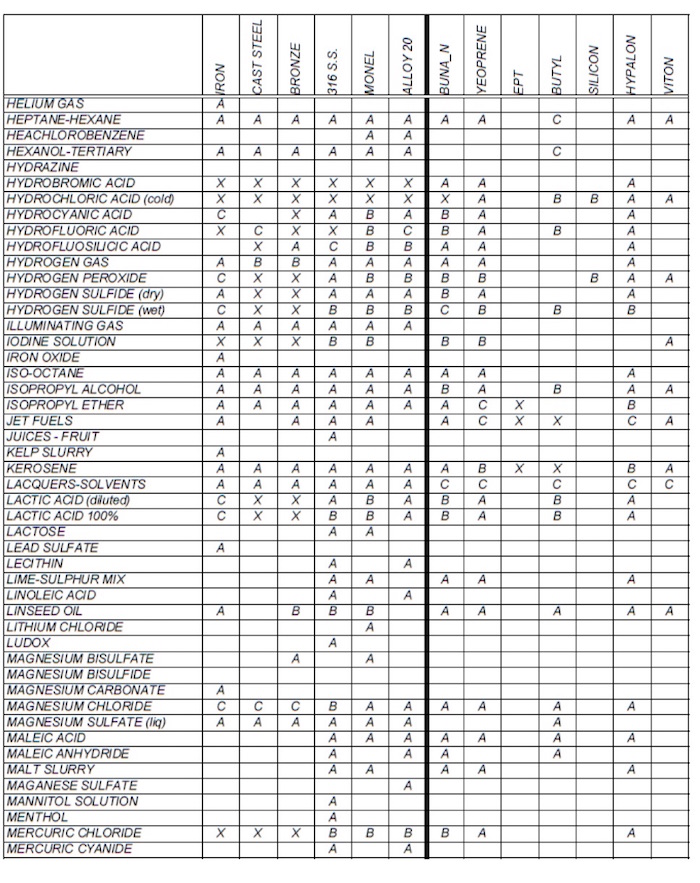

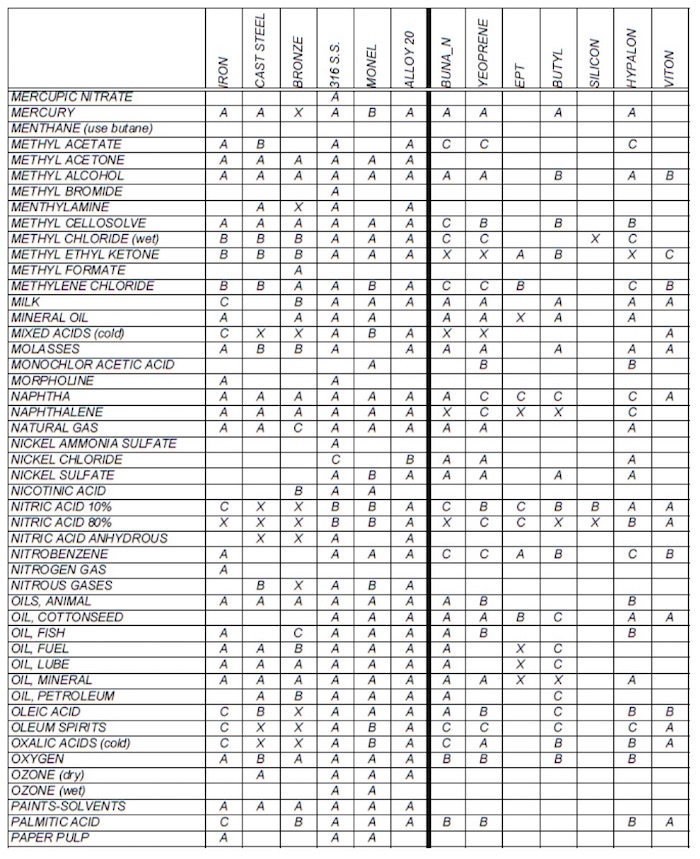

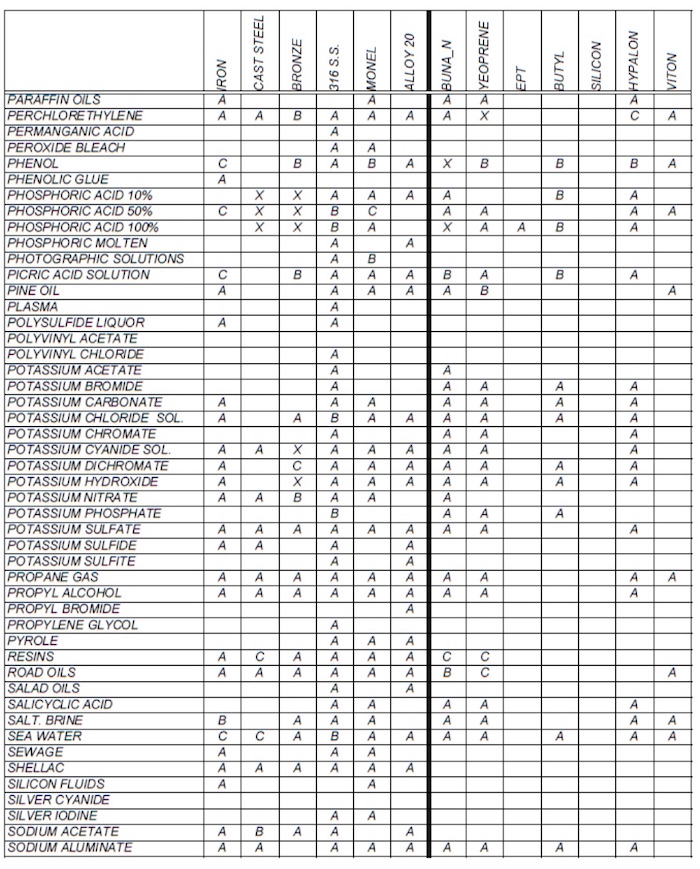

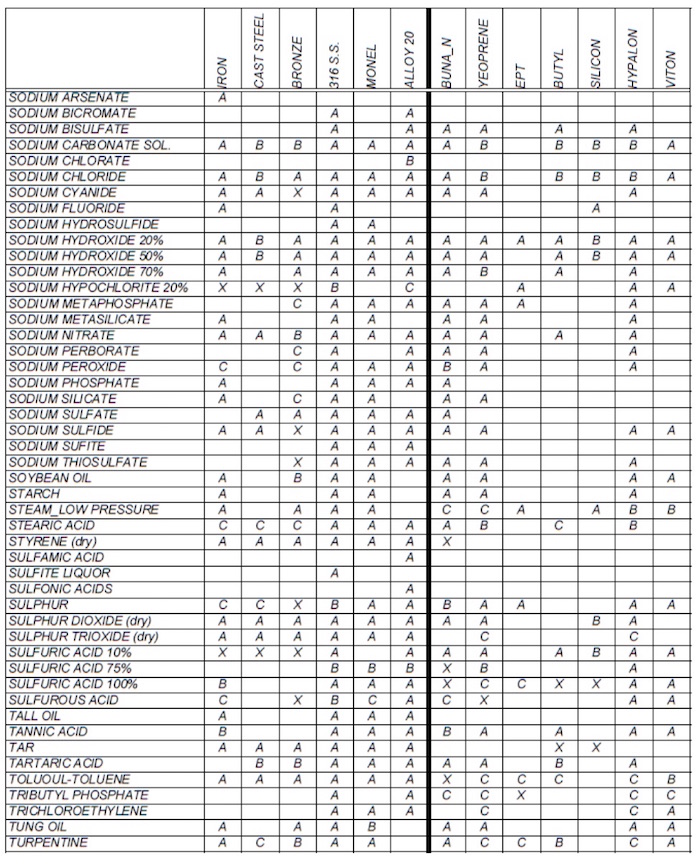

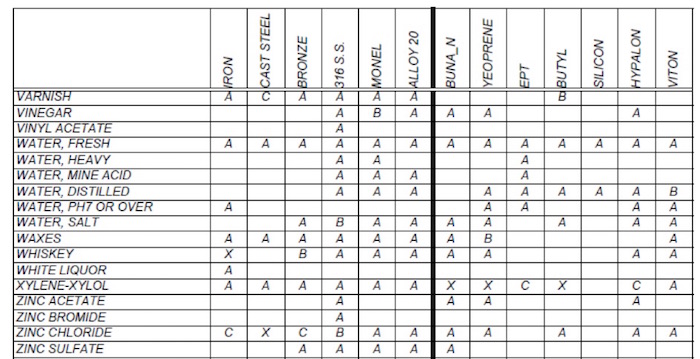

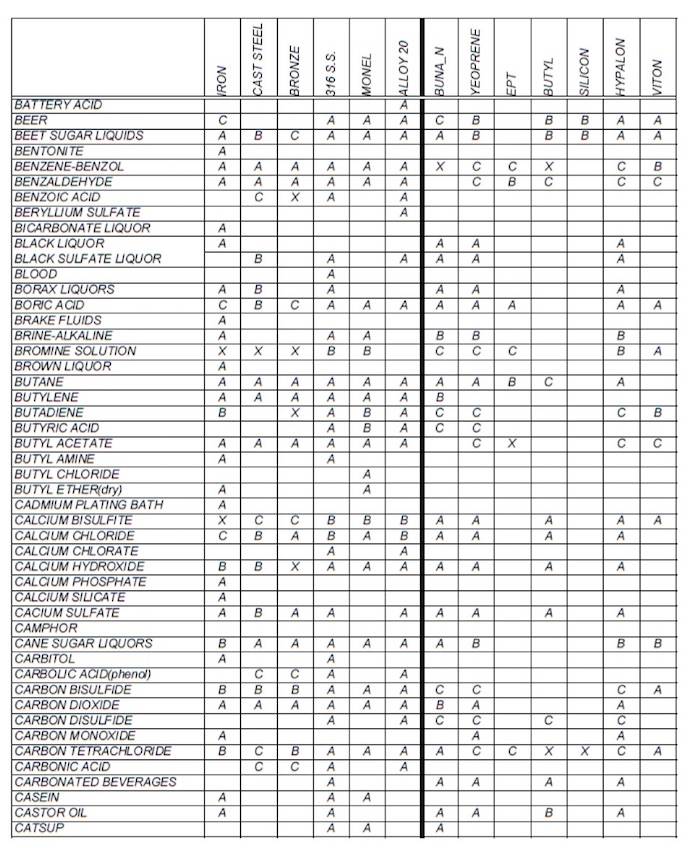

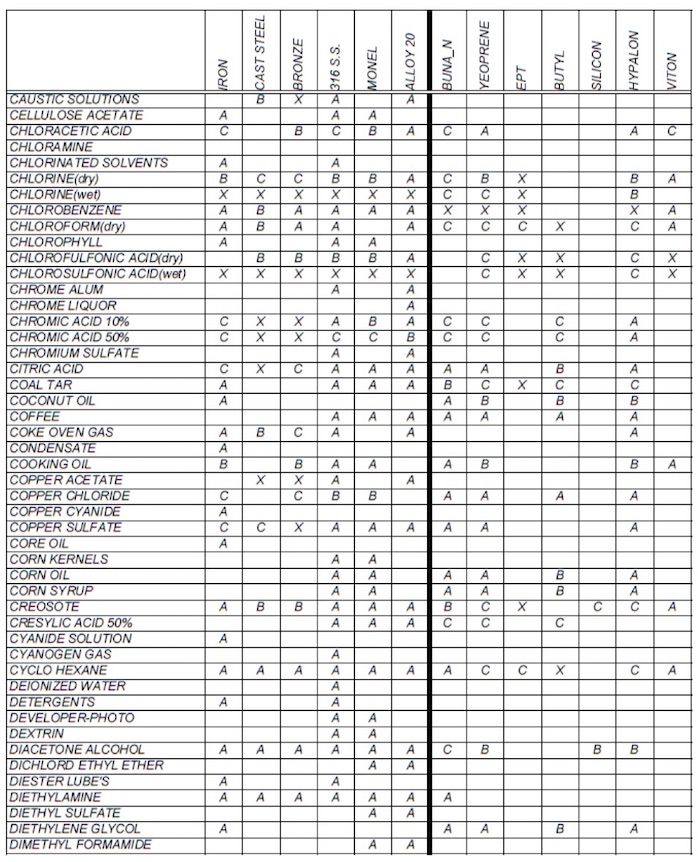

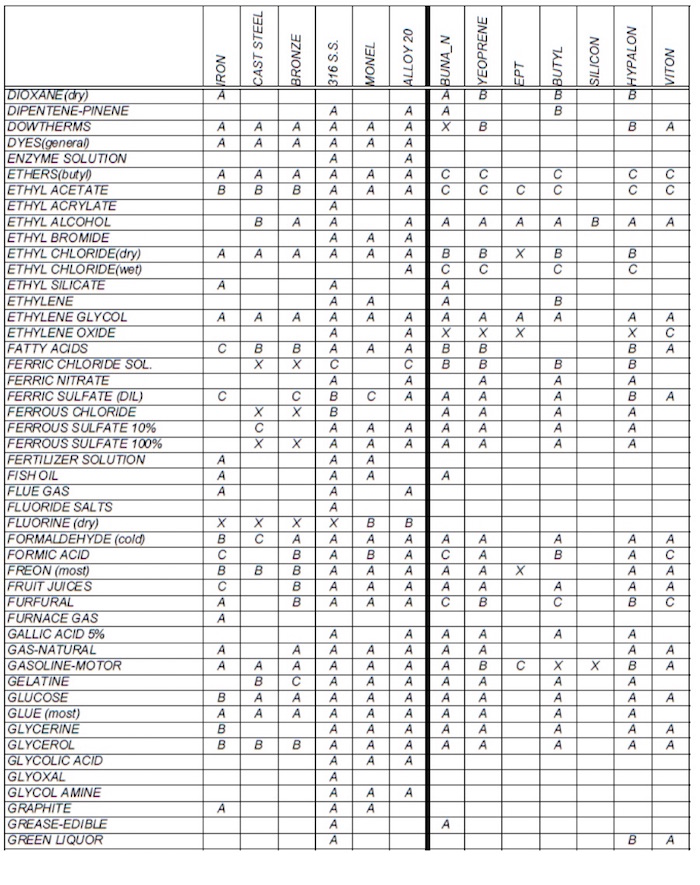

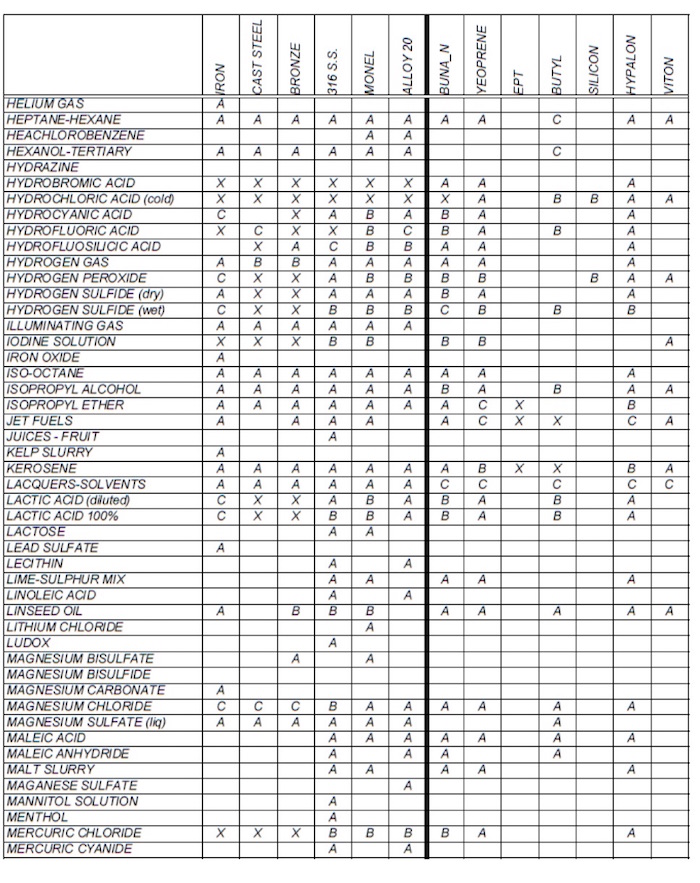

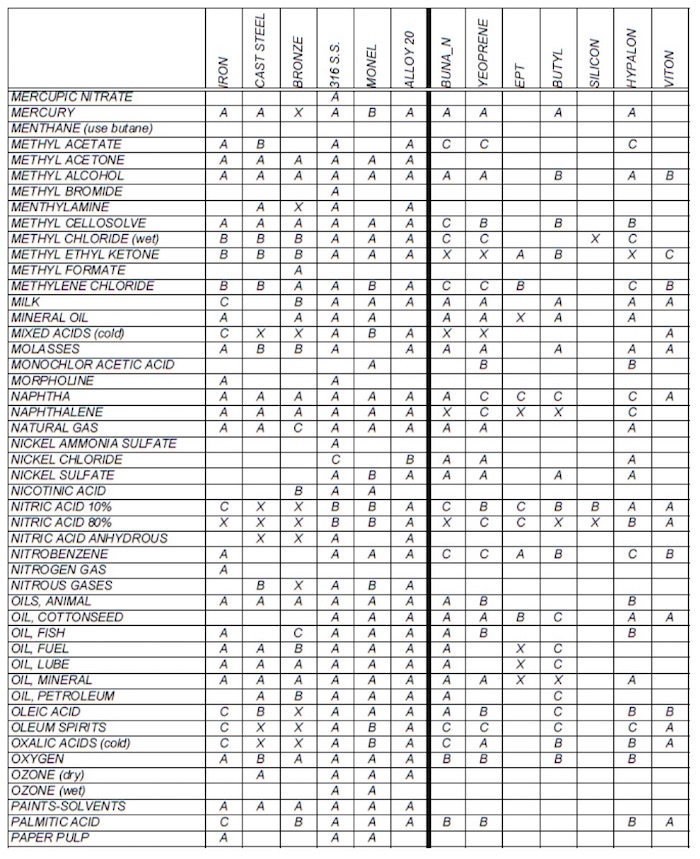

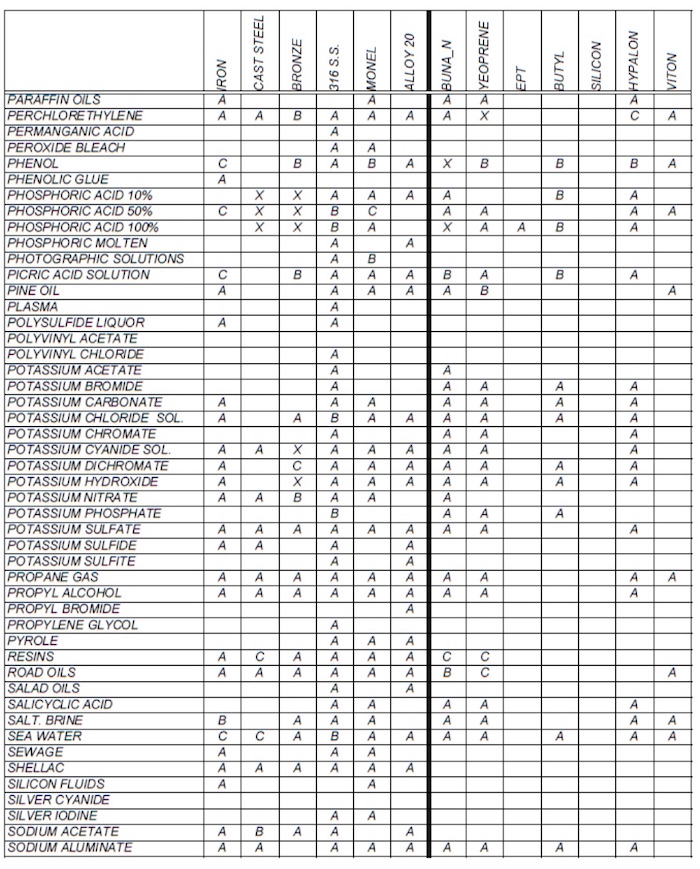

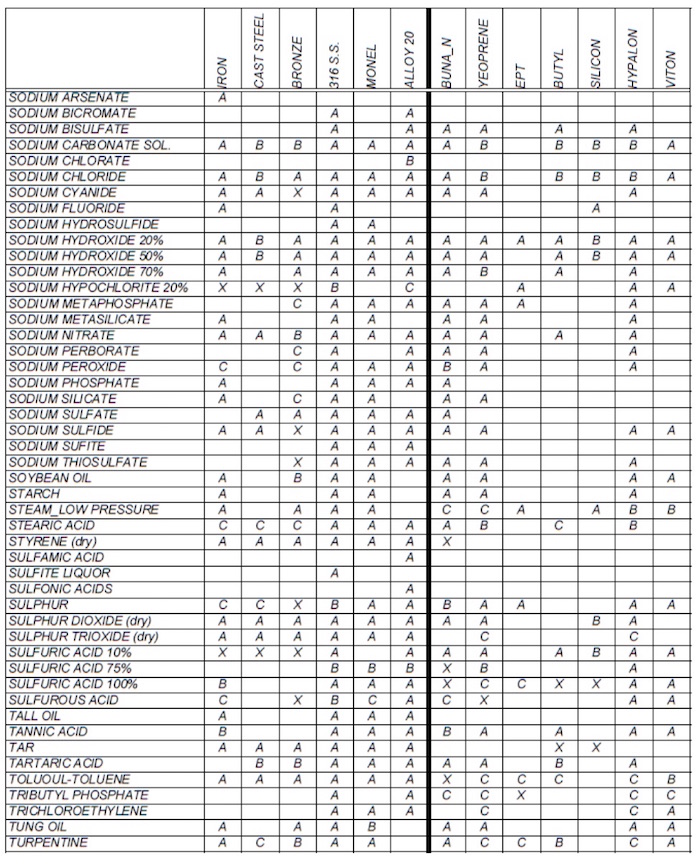

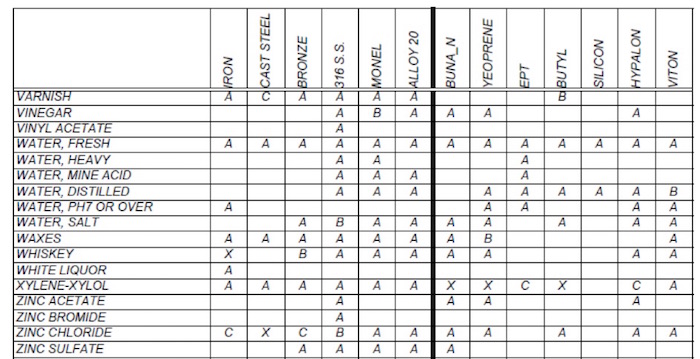

Following Table 4 shows some recommendations for selection of materials for valve parts in relation to working fluid. This is empiric recommendations and should be used in accordance with your own experience, thus these recommendations come with no guarantee.

Table 4 materials selection

A - Generally should give satisfactory service with no adverse effects.

B - Generally a slight to moderate effect. Use only when nothing better is available.

C - Generally a moderate to severe effect. Considered as unsuitable.

X - Generally unsuitable under any condition.

Caution is always advised and all of the above mentioned factors (temperature, pressure etc.) should be taken into account before confirming selection of materials for particular application.